Whether you’re a company that employs people who regularly work at height, or a business premises owner looking into your legal obligations around roof safety, it’s important to make the right decision regarding roof safety systems.

Business premises owners are often under the impression that, as they hire contractors to carry out maintenance work which requires roof access, they don’t have any obligation to providing a safe environment. As we discussed recently, that’s not the case! (Click here to view our blog).

Many companies who regularly work at height will provide personal protection equipment (PPE), including a harness to be clipped to a guide line whenever the person is working at height. While this is a good secondary solution, there are problems with relying on it.

First, it requires the business premises to have a safety guide line in place. Without this, there is little point in the harness as it won’t clip to anything!

The other problem is that a safety line will often operate around the perimeter of a roof or to limited areas. If a worker is clipped in, this restriction could prevent them from carrying out a job to their best abilities. A taut connection between harness and guide line creates a tripping hazard, particularly if more than one worker is in the area at the same time. In addition, should there be more than one person in an area at a time, to safely operate they must move in sequence depending on the order they are clipped onto the safety line. In reality, it is likely they will clip on and off to move more freely, which negates the point of the safety line.

Finally, the safety guide line system relies on human interaction. The harness must be climbed into and secured, and the safety line clipped to at all times. When moving across a roof, it can be tempting to unclip and walk the shortest route to the plant which requires maintenance. As soon as the worker is unclipped, risk is instantly raised.

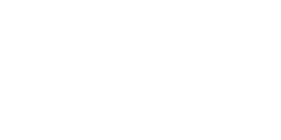

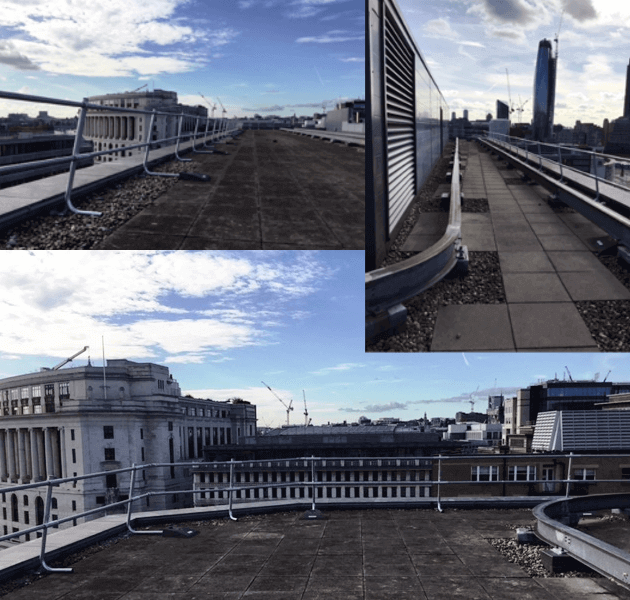

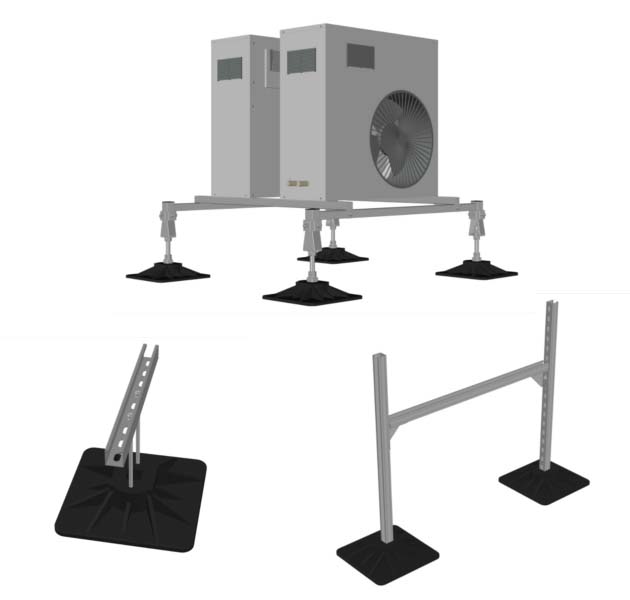

A roof safety rail system, whether freestanding or fixed, gets around these problems. There is far less time required for safety set-up of a job, without the need for checking and setting up harnesses. A worker can immediately access any area of the roof without the need to worry about clipping on and off a line: permanent roof safety rails allow free movement.

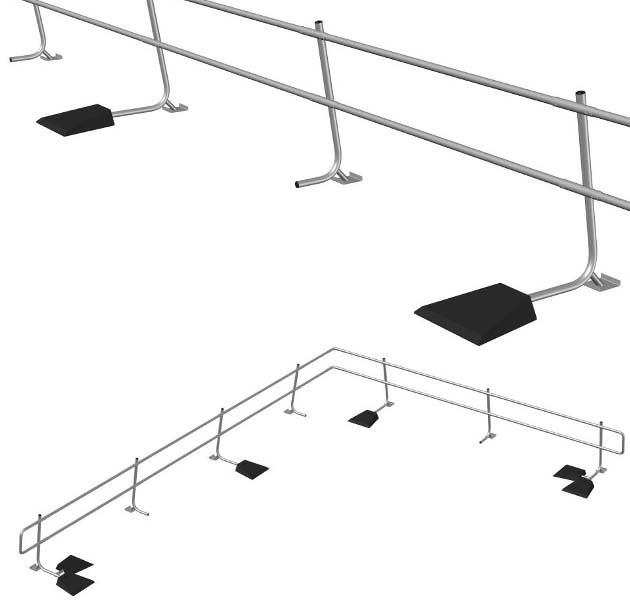

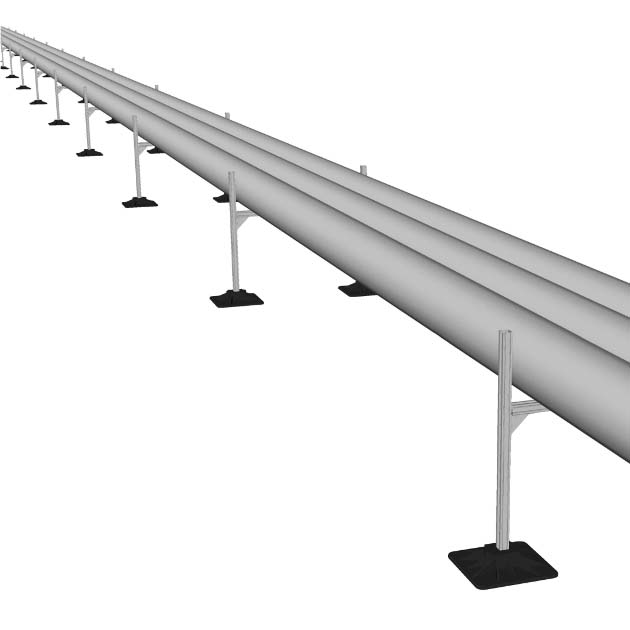

There are other ways to keep the roof area safe for maintenance workers, such as using cable trays raised off the floor level to eliminate or mitigate trip hazards. Some businesses may worry that allowing free access across the roof will raise new hazards, such as workers coming too close to fragile objects like skylights.

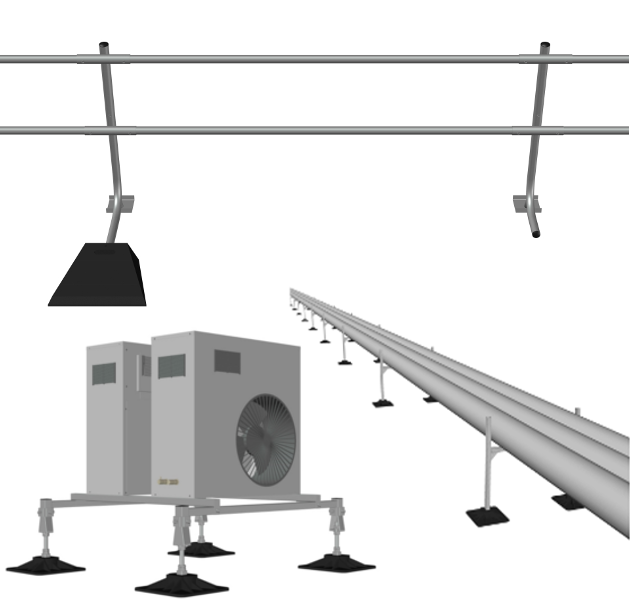

A safety rail system can be installed in a modular fashion, restricting access only to certain areas of the roof if required. Alternatively, frames such at the Rooflight Protection System can be used around fragile objects or potential hazards to mitigate the risk.

The final benefit to a roof safety rail instead of a guide line system is that it allows for easy movement between levels. On a multi-level roof, using a line can be cumbersome. A safety rail allows free movement, while modular step-over units mean it is quick and easy to access different levels.

So there you have it: harnesses add additional protection, but can delay and complicate even simple jobs when working at height without a safety rail in place. To find out more about the different types of roof safety rail (fixed and freestanding), keep an eye out for the next blog. If you can’t wait that long, remember you can always give us a call to talk about your latest project requirements.