What happens when your fragile roof goes wrong?

Your business premises will have some plant which needs maintenance at regular intervals. To manage this, you either have an in-house team, or you'll get contractors in to perform all required maintenance. However, with fragile roofing areas such as skylights a common obstacle for maintenance workers, how do you keep them safe?

You may feel that, by employing a specialist roofing contractor, responsibility of safety is transferred to them. However, you still have full responsibility to anyone on your premises. Time and again there are stories in the news of workers falling while working at height - including through fragile roof areas.

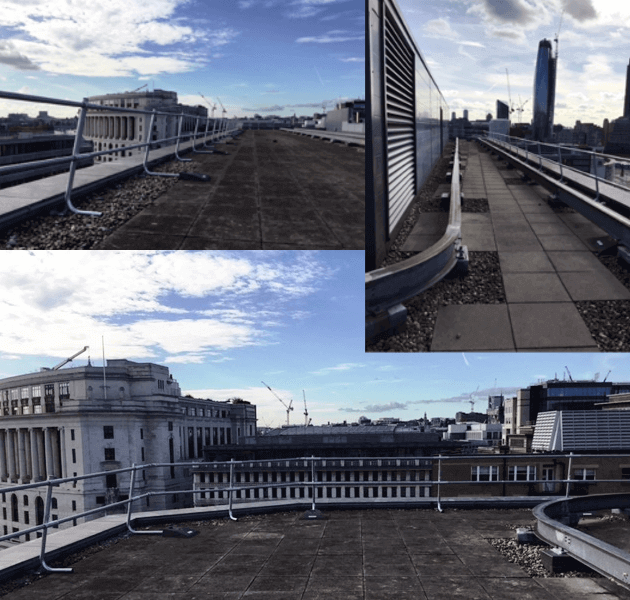

You probably have all of the perimeter safety rails, up-and-over ladders, and cable trays across your roof. But what about identifying - and protecting - fragile areas?

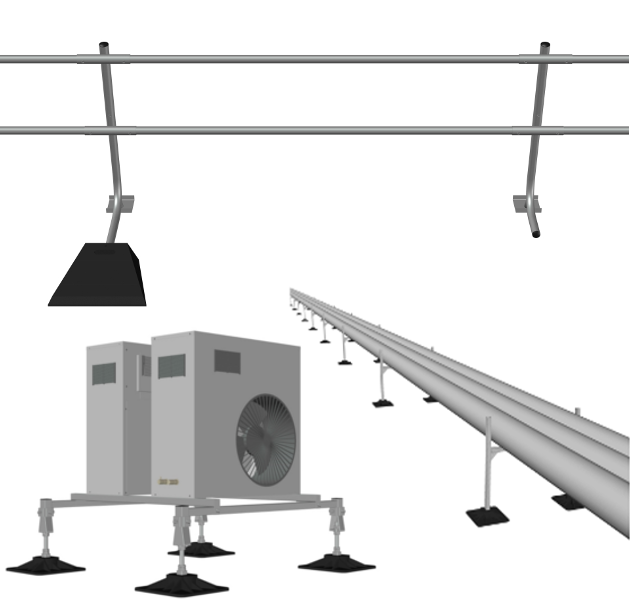

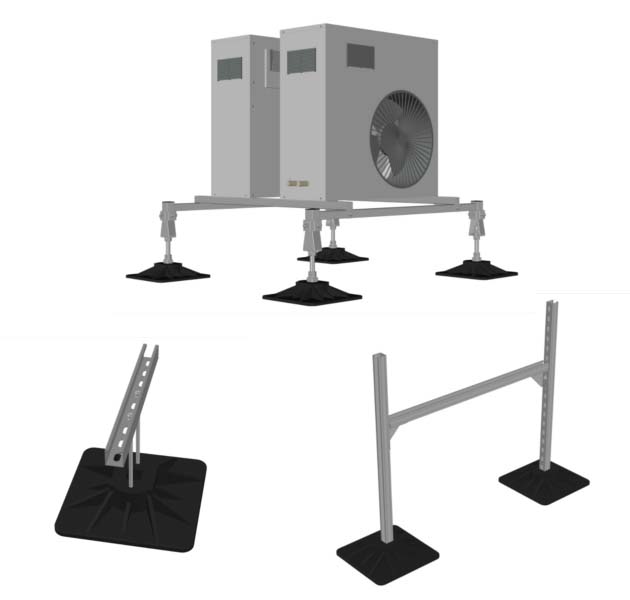

Plant often sits in hard-to-reach areas of the roof, accessed by ladders and platforms. It can be easy to focus only on the immediate safety of the environment, but it's crucial to assess the wider roof area in case of a short-distance fall. For example, an AC unit placed on a raised platform may only require a few steps up a ladder to reach it - but if this is placed near to a skylight, there is risk that what could be a short hop down turns into a very long fall through the skylight.

There are ways to reduce risk on fragile roof areas, though, and if you're sending any maintenance workers up to the roof on your business premises, it's worth considering the following...

1) Mark off the area

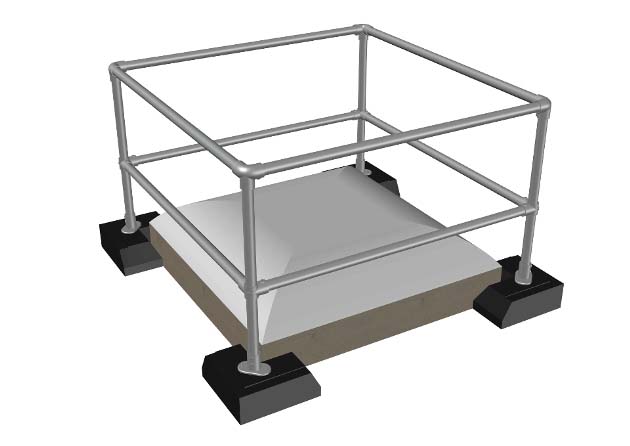

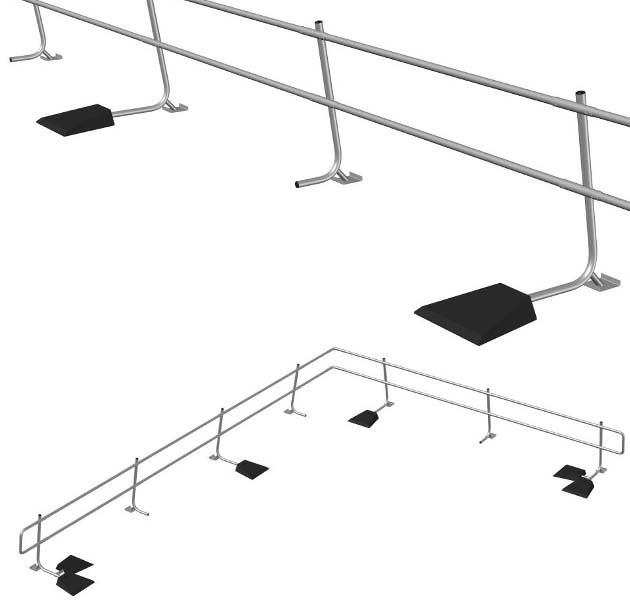

Using freestanding railings, you can place a safety perimeter around any area of the roof which could pose a hazard. Freestanding rails are ideal, as these take little time to install, don't fall over in high winds, and don't require any structural drilling to be fixed in place.

A freestanding area protection rail, such as our Rooflight Protection System, is designed to prevent anyone from even getting close to the fragile area. With no drilling into the structure required, and even weight distribution around the fragile zone, it’s an ideal solution to preventing falls from height caused by fragile roof areas.

The flexibility of a freestanding safety rail also makes it an ideal temporary solution while a more permanent fix is put in place. For example, if you are aware of problems with structural integrity of an area of your roof, a freestanding rail can be quickly and easily put up to prevent access to the area until a permanent fix is put in place.

2) Create a safe pathway

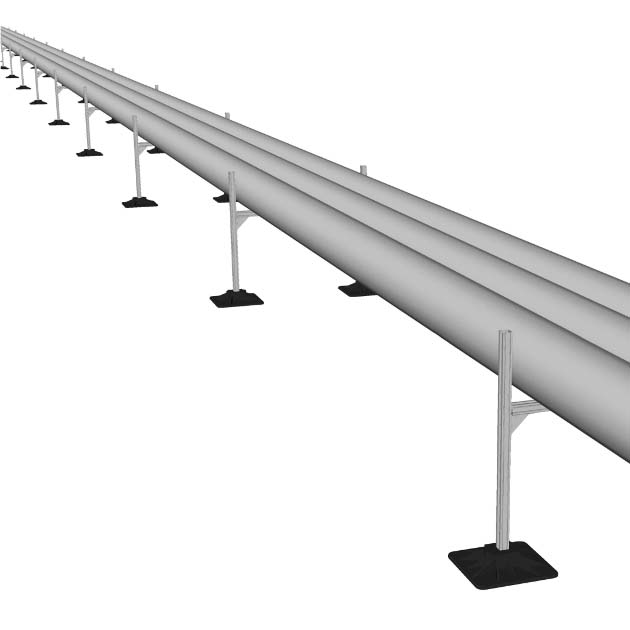

If you have several fragile areas on your rooftop, such as a series of skylights, consider marking out a safe path for access to plant units using safety rails. This could be a perimeter-based rail, or a path determined by two parallel rails. Entrance and exit to this path can be determined by self-closing spring-loaded gates, for additional security and clarity on where it is safe to move freely around the roof.

3) Use plenty of signage

Make sure to highlight the possibility of a fragile roof and working hazards, such as cables or obstructions, by using printed signage. Using these wherever possible can help to reduce your liability as a business should an incident affecting the health and safety of roof contractors occur.

4) Consider moving plant to a safer location

If possible, consider moving equipment that requires maintenance to a different location on the roof away from fragile areas. This may require additional work such as the introduction of more cable ducting, but it will ensure a safe working environment for all future contractors. You could also consider raising plant systems onto a frame, to make them easier to access and more visible on the roof environment.

The Cost To Your Business

Adding railings, pathways, plant frames, or marking safe routes may seem like an additional expense - but it's worth it. If an incident were to occur on your premises, you're responsible - unless you can prove all reasonable steps have been taken to avoid such an accident. Working at height regulations mean you have a liability to your staff and to any other contractors or visitors on your premises, and while you could do the bare minimum to cover yourself (such as a less-effective clip-on safety rail instead of a permanent perimeter rail), the cost to your reputation in the face of an incident is far worse.

Your insurance premiums will go up, no doubt, and you'll be faced with a PR nightmare to tackle should the incident result in a fatality that hits the news – not to mention the financial implications should you be found negligent. It's worth the initial investment to protect your fragile roof, and anyone working at height on the roof, to prevent future insurance claims, administrative burden, and financial losses.

If you're not sure what solution works best for your business premises, just get in touch. One of our guardrail engineers will be happy to have a no-obligation chat to give you some ideas to protecting your business and your reputation.