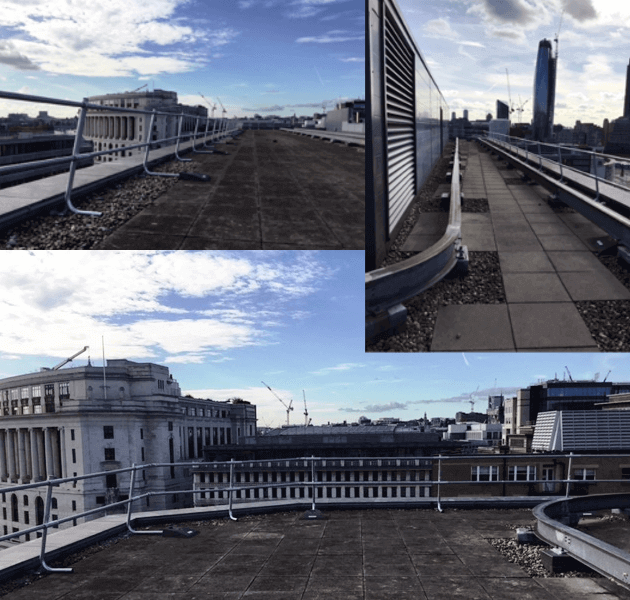

A roof safety system isn't the first thing you think of when building or updating your premises - but it's an important consideration when working out your project budget. As a premises owner, you're legally obligated to provide a safe environment for anyone working at heights. While there are other systems, such as safety lines with harnesses, a roof safety rail will guarantee your compliance regardless of who will be accessing your rooftop.

Things to Consider In Your Roof Safety System Budget

Whether you're working on a new build or updating current premises, there are several things to keep in mind when budgeting for your roof safety system.

Firstly, determine where access is required. Is it for the whole roof, or to a selected area or areas? You can minimise cost if your plant which requires maintenance is only in a small area, by placing railings with gates to create safe pathways, instead of an entire perimeter around the rooftop.

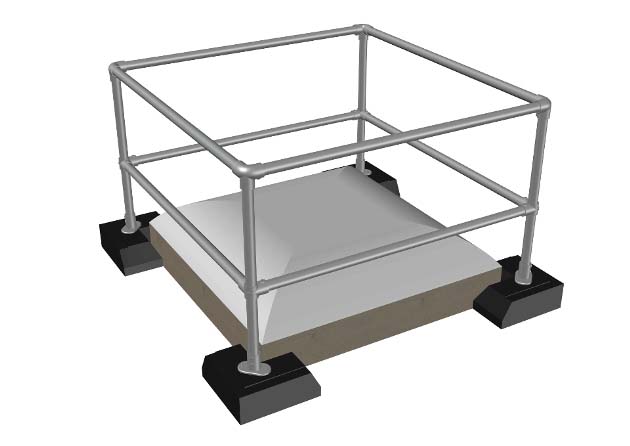

Are there any level changes on the roof? If your roof is multi-leveled, or your plant which requires access is raised up, you'll need to consider the safest access options. This could be vertical ladders, up-and-over units, or platforms for safe movement and access.

Do you have any fragile areas within the maintenance zone? For example, skylights can be safely fenced off to leave the rest of the maintenance area free.

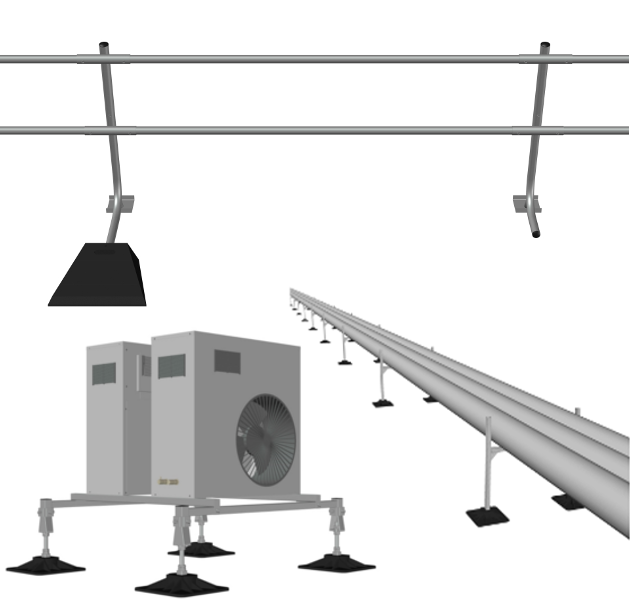

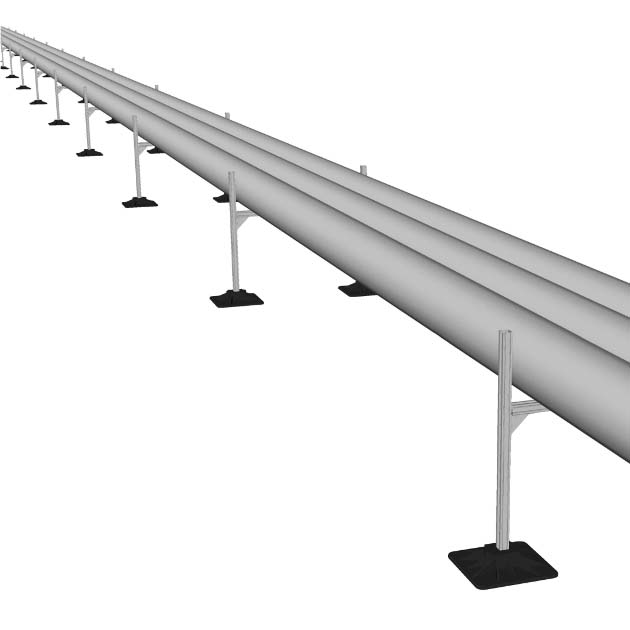

Finally, are there any trip hazards which need to be taken into account? For example, cables lying on the roof, instead of raised in cable trays, can cause a trip hazard for which you are liable. Using trays to raise cables off the ground makes them more visible, mitigates the trip hazard, and makes them easier to access when working on cabled systems.

Choosing Your Roof Safety System

We've already taken a look at the differences between safety lines with harnesses and roof safety rails, but it's worth taking into account how your roof system will be fitted.

Some roofing structures, such as parapets on the perimeter, can limit the type of rail put in place. You can, however, use something like Rhinorail's Parapet System, which are designed with special clamps in place of drilled fixtures.

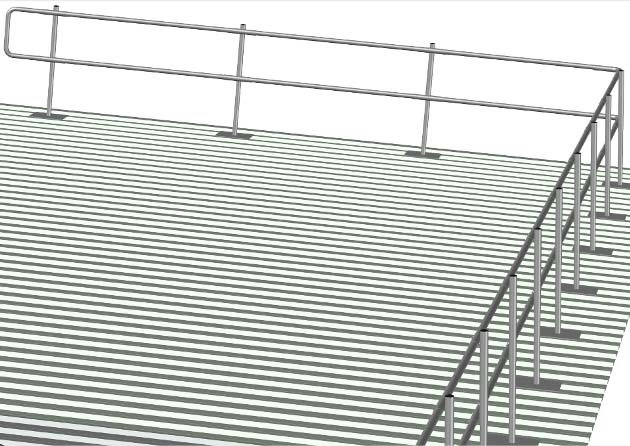

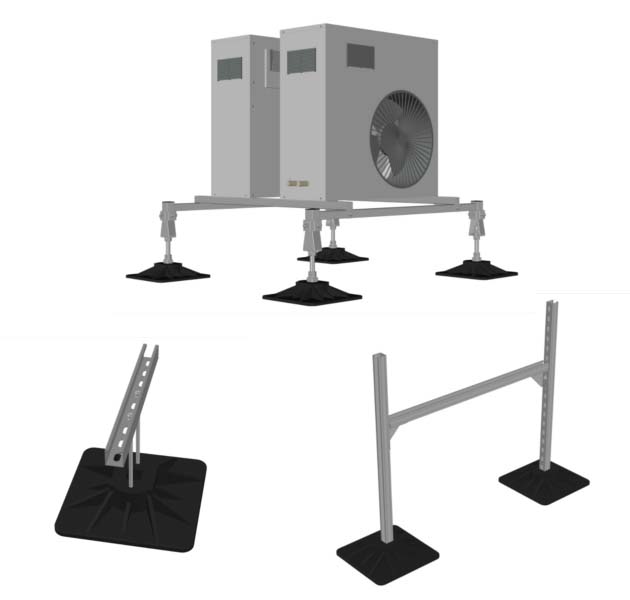

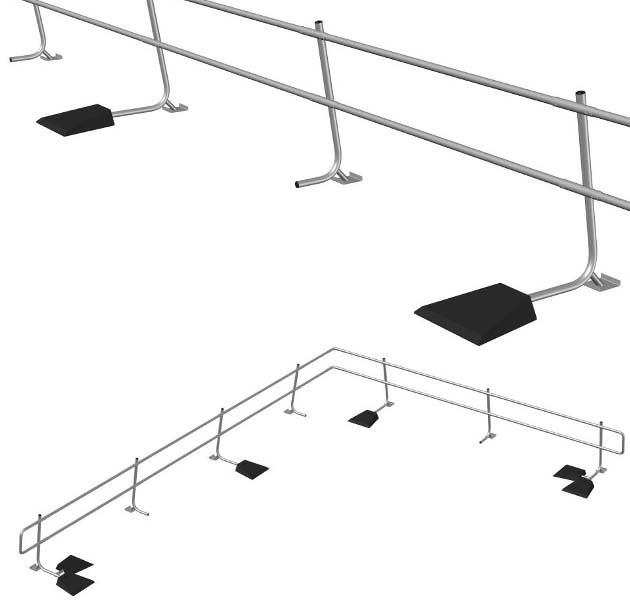

It's also worth taking into account your installation time, and the structural quality and set-up of your roof. For example, a corrugated metal roof would need to have a Rivet Fixed Guardrail that has larger footplates to straddle the troughs across the roof. On the other hand, a Freestanding Guardral Systemenables true flexibility of configuration across any flat roof.

The type of roof safety rail you choose will also affect your installation times and costs. Some roof areas are only suitable for fixed (drilled) safety rails, which takes more time to construct than a freestanding modular system. These costs for install should be factored into your budget.

Measuring Up For An Accurate Quote

Once you know which type of roof safety rail(s) you're going to need, it's important to measure up accurately how much of each type of rail you're going to need. Once you have this information, you can easily cost up for additional necessary components, such as the weights to hold down freestanding systems, corner setups, spring-loaded gates, and vertical or platform access.

IF this sounds too confusing or time-consuming, we can help. We can design a bespoke CAD layout of your roof, with your required rail type(s), and work out exactly what you need. This helps you to avoid overspend and enables you to calculate labour time more accurately, too.

If you'd like us to help you with a quote for your roof safety rail, get in touch!