"

Pressford Safety Services, a safety and maintenance at height specialist, used 330Lm of our Rhinorail Freestanding System for their project at the Times Square Building on Queen Victoria Street, London.

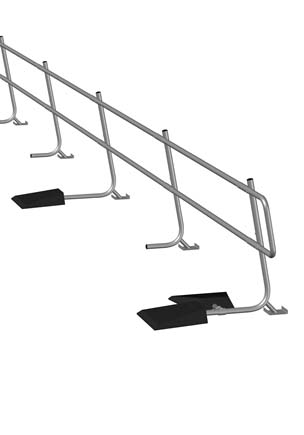

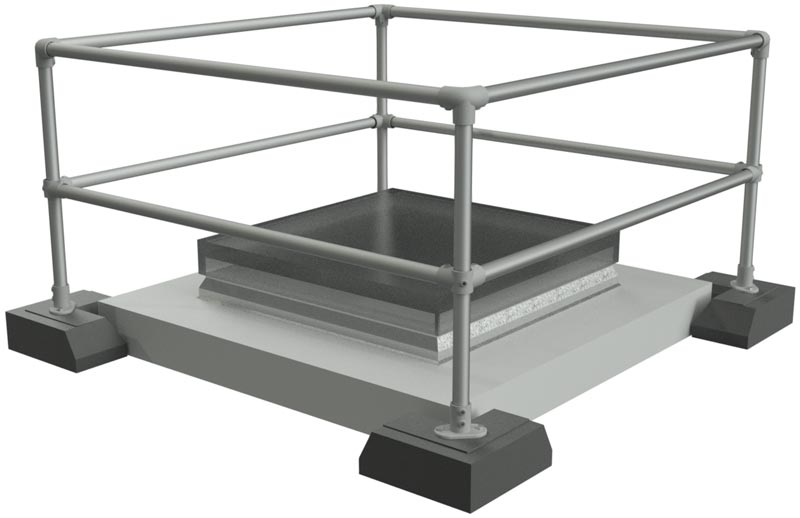

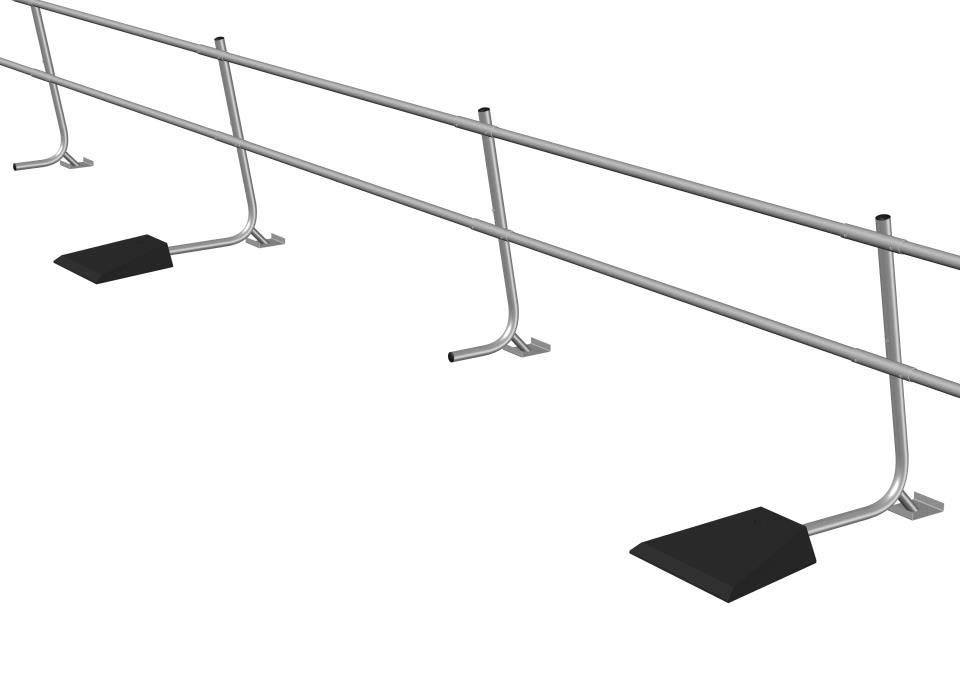

The freestanding rail allows for full flexibility of design, as there is no need to drill into any structures. The quick and easy install meant the building had a suitable roof safety system set up in minimal time, with no noise disruption, thanks to the zero drill requirements of the railings.

Held fast by the 20kg counterweights, the continuous freestanding system covered the entire perimeter of the roof, using a mixture of 90 deg swept bends and variable elbows to suit.

The roof had a pre-installed cradle track which in some areas ran very close to the roof edge. This didn’t stop the system being installed continuously as the components that make up the freestanding kit can be easily manoeuvred into place.

The full perimeter system ensures that maintenance contractors accessing the roof can carry out surveys and repairs wherever necessary and know they are 100% protected from any falls or injury.

To find out more about the project, you can contact Pressford Safety Services using the email info@pressfordservices.com or on 01634 292081.

"

.jpg)